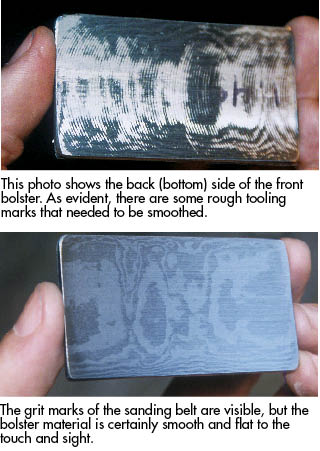

I use permanent double-stick tape to stack and adjoin the top and bottom bolsters together. I sand until all surfaces that will come into contact with other surfaces are completely flat. In this case, I remove the tool marks off the bottom of the top bolster (I don’t have to worry about the topside of the top bolster right now), and both sides of the bottom bolster. The latter will be coming into contact with not only the bottom side of the top bolster, but also with the knife body, as well as with table surfaces in sawing, grinding and drilling applications.

I do not overlap the strips of tape. Instead, I lay them down carefully, side by side, so that they lie on the same plane. Otherwise they could be off of square by a few thousandths of an inch.

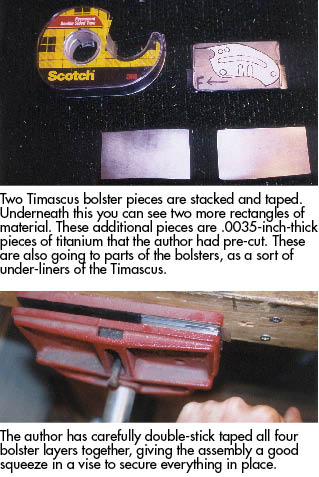

Be careful to get the proper double-stick tape. 3M makes a permanent version (color coded red) and a not-so-sticky version (color coded blue). This can be confusing because the overall color of both packages is yellow plaid. Make sure you use the red version. The blue version will not hold up through the bolster-making process and is likely to fail to hold the pieces together in their proper places.

Layered Bolsters

In the accompanying photo, you can see the two Timascus pieces stacked and taped. Underneath this you’ll discern two more rectangles of material. These additional pieces are .0035-inch-thick rectangles of titanium that I have pre-cut. They are also going to be a part of the bolsters, as a sort of an under-liner of the Timascus. I felt the Timascus thickness was a bit too thin in regards to the proportions of the rest of the knife.

The additional bolster layer will thicken things up a bit, as well as give another visual element to the overall design of the knife. Another layer underneath the bolster will give the knife a dynamic and dimensional appearance. It is also one more layer to work with a file and/or anodize. I have been using this idea for a while; it’s more work, but adds a nice touch, something you don’t otherwise see on knives.

I have carefully double-stick taped all four bolster layers together and am now giving the assembly a good squeeze in a vise to secure everything in place.

I trim the excess tape from the sides with an X-Acto blade. This excess tape will get in the way otherwise, catch on work surfaces and clog up with grit when I start cutting. I suggest getting in the habit of working cleanly and orderly. It will save unforeseen headaches.

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.