Knowing what you don’t know sometimes means knowing when to stop researching and just play with your knife. In the course of more fully educating myself about knives, I find that everything, and I mean every little thing, involves further study. It can be paralyzing. And sometimes it needs to just get silly so I can stop worrying about it.

I’m in charge of maintaining the style sheet at BLADE, which is an alphabetical list of knife industry-specific terms and instructions—or exceptions to instructions—regarding how we present certain things in BLADE. We want to be consistent.

The other day my boss and BLADE editor, Steve Shackleford, sent me something like, “Just so you know… the V in MoV is always capitalized. For example, 8Cr13MoV: Cr refers to chromium, Mo refers to molybdenum and V refers to vanadium—all elements in the steel mix.”

Cool, I thought.

And then I thought: The periodic table of elements? Seriously?

For an English major with a history minor—even one into guns and knives—this concerned me. Oh sure, there’s science in the acids and bases of a batch of cookies in the oven, but I honestly never imagined printing out that chart after I left high school. But there it lies, adding color to the growing pile, its information so obvious in hindsight. Jim Bowie perpetually scowls with what I imagine can only be his disappointment in my slow pickup.

So, when Steve explained how BLADE presents Rockwell hardness: “the Rockwell hardness is 58-59 HRC,” I figured I should try to fit more about that topic into my rock hard head.

After work I called a friend.

His response: “What is the Rockwell hardness scale and what does it mean to me?”

Exactly, I replied.

And while we’re at it, I thought, aren’t “hard” and “tough” synonyms for the same thing, like soldiers or overcooked steak? (That’s a joke. You can read about the difference between hardness and toughness in Bernard Levine’s article, “Rockwell Hardness, What It Is And What It Means To Your Blades,” BLADE Magazine, Sept. 1997, Pages 74-76.)

And why can’t I close my Twitch II? Am I not pressing hard enough? Am I afraid of the release? (That’s not a joke, and no, the lock is not engaged.)

“I can envision both scenarios,” my friend said.

That’s how he talks.

We joke about cut-resistant gloves, only he’s not joking. I’m a klutz.

He explained something about measuring divots and my ears stopped up and my eyes glazed over. I have a hard time thinking in 3D.

But I had the power all along. In the archives of BLADE itself I found this helpful article: Bernard Levine’s article, “Rockwell Hardness, What It Is And What It Means To Your Blades,” BLADE Magazine, Sept. 1997, Pages 74-76

It all makes perfect sense. I think I can now move on to worrying about whether there’s a good mix of ATS-34, 440C, CPM S30V, CTS steels and 5160, O1, D2, 1095, L6 steels represented in our Knifemaker Showcase pieces.

Your Knifemaking Questions, Answered

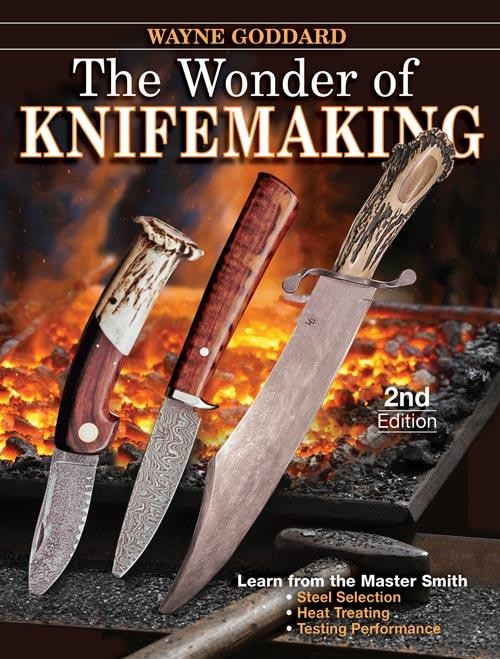

Get all your knifemaking questions answered in this collection of expert advise from former BLADE columnist Wayne Goddard. The Wonder of Knifemaking makes a thoughtful gift for someone interested in starting or perfecting their knifemaking skills

Get all your knifemaking questions answered in this collection of expert advise from former BLADE columnist Wayne Goddard. The Wonder of Knifemaking makes a thoughtful gift for someone interested in starting or perfecting their knifemaking skills

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.

Erin, Great post, I like your style-open, innocent, vulnerable- rare qualities in the knife world. And since I like to cook, I find your cookie analogy is very appropriate. Today’s Particle Metallurgy steels (CPM) are just like a batch of chocolate chip cookies. They take elements Iron, Carbon, Chromium, Manganese, Vanadium, and even Niobium and Cobalt, “stir” these together according to their secret recipies and bake in a plasma “oven” at dizzying temperatures that would vaporize mortals. The resulting “Billet” is hot rolled into sheet, descaled, and shear cut. Then fools like me take these bars and grind or forge them (I’m the only one) into knives. The Issue of Rc hardness has a great deal to do with the edge holding and ultimate sharpenability of those knives. Higher Rockwell #’s mean more wear resistance, but decreased toughness (think brittle) and impossible to sharpen. While Rc #’s in the tall 60’s may be impressive, they do nothing for a knife. If it can’t be sharpened, edge holding is irrelevant. So I temper my own knives to a 59-60 Rc.

Thank you for the kind words. I laughed out loud over your “plasma ‘oven’ at dizzying temperature that would vaporize mortals” line! I didn’t get more into the edge holding-brittleness divide because I was hoping to steer people to the old BLADE article that explained it better than I ever could. As a land surveyor’s daughter it was unnerving to learn that things like bridges were not solid, immovable objects and actually swayed in the wind. So I actually do understand what you’ve explained here. My theory is that there are always people who would like to learn more about knives, but may be intimidated. I have no such pride. I’ll be doing a lot more pieces like this as I learn more. Thank you again for taking the time to write and the warm welcome.