The BLADE Magazine Cutlery Hall Of Fame® is proud to announce three most-deserving inductees for 2022: the husband-and-wife team of Mr. and Mrs. Aldo and Edda Lorenzi and Bill Ruple.

All will be formally inducted in a special Cutlery Hall-Of-Fame ceremony and breakfast during BLADE Show 2022 June 3-5 at the Cobb Galleria Centre in Atlanta.

One of the most prolific, long-running supporters of custom knives in modern cutlery history, the Lorenzis forged a name known in knife circles far and wide while operating their G. Lorenzi retail knife store in Milan, Italy, where they sold knives of some of the greatest knifemakers of all time, including Cutlery Hall-Of-Fame members Buster Warenski, Bob Loveless, Michael Walker, Jimmy Lile, Gil Hibben, Ron Lake, Frank Centofante and many more.

Meanwhile, hailing from Pleasonton, Texas, Ruple is one of the most successful slip-joint makers of the 21st century, winning many awards for his traditional pocketknives, and also serving as a teacher and mentor to an entire generation of award-winning slip-joint makers from Texas and elsewhere.

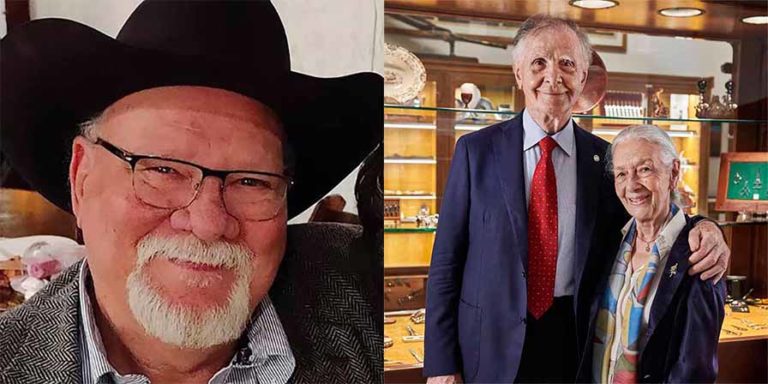

Aldo And Edda Lorenzi

Aldo and Edda Lorenzi operated G. Lorenzi retail cutlery store in Milan from 1959 until its close in February 2014. The Lorenzis regularly attended the world’s most important knife shows, buying scores of knives for sale in their shop. They bought so many knives at shows, in fact, that the Lorenzis’ presence often determined a show’s success or failure. The support and exposure they gave to American makers in particular by selling their knives in their store in one of the most exclusive shopping areas in Milan was pivotal in introducing American custom knives to Europe.

In 1995 they won The Knifemakers’ Guild’s prestigious Nate Posner Award “in recognition for outstanding service in the promotion of handcrafted cutlery.” They also won the BLADE Magazine 2014 Industry Achievement Award for their decades of supporting the custom knife industry. For five years ending in 2019, they sponsored the Aldo and Edda Lorenzi Award for the Guild Show and the BLADE Show, with each event’s award-winning maker receiving $1,000 cash and a plaque—10 awards and $10,000 in all. The Lorenzis also are most supportive of the William F. Moran Foundation and are one of the Foundation’s first chartered member couples.

“More loyal ambassadors of the art cannot be found,” one sitting Cutlery Hall-Of-Fame member noted of the Lorenzis. “Their store was like a museum, always welcoming visitors and ready to educate them on fine cutlery and custom knives. Several prominent collectors got their start by buying a custom knife at the Lorenzis’ store.”

In fact, the Lorenzis have assembled their massive collection of over 2,000 knives (including 150 custom knives by the world’s best makers spanning the past half century), 700 books, 1,000 magazines and prints, and related items in a new state-of-the-art museum in Milan (December BLADE®, page 60). The museum contains the knives in elegant oak display cases, a recreation of the copper-paneled room that featured the small entrance door to the G. Lorenzi store in Milan, a wooden portable knife grinder used by Aldo’s father and the store’s namesake, Giovanni Lorenzi, almost a century ago, and much more.

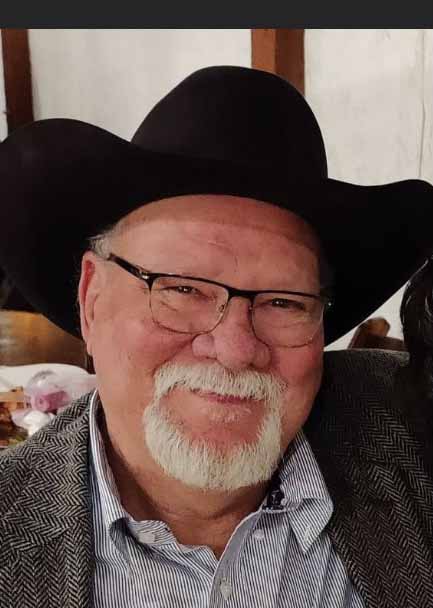

Bill Ruple

In the eyes of one sitting member of the Cutlery Hall-Of-Fame, Bill Ruple, an award-winning custom knifemaker specializing in traditional pocketknives/slip joints and multi-blades, has done as much as anyone to promote the knife business. Bill served on the board of the Texas Knifemakers Association, taught many how to make traditional knives and is very free with his knowledge. In recognition of this fact, he was presented with the BLADE Show 2019 Aldo and Edda Lorenzi Award. The award went to a knifemaker who excels in terms of teaching and mentoring his or her fellow makers in the art of knifemaking.

Having built knives for 34 years, Ruple is a premier maker of slip joints and possesses a selfless willingness to teach others how to do it, usually in his shop in Pleasanton, Texas, and also at BLADE University, the BLADE Show, BLADE Show West and other venues. He has helped many get started with the slip joint, one of the oldest yet most challenging folders to make. His kindness and patience validates something other makers know all too well—that he is most willing to share knowledge with and encourage, critique and mentor makers everywhere.

Bill has taught quite a few who have become award-winning makers in their own right, including Rusty Preston, Luke Swenson, Tom Ploppert, Phil Jacob, Bubba Crouch, Toby Hill, Enrique Pena and others. A number have gone on to teach also, spreading Ruple’s knowledge to others who no doubt do the same as well. Bill does not limit his shared knowledge to just stock removal makers, receiving the American Bladesmith Society’s President’s Award for teaching ABS members how to make slip joints. Finally, Bill has donated some of his knives to knife shows and other cutlery organizations to raise funds for their various needs.

Hall Of Fame Criteria

Selected by a vote of sitting Cutlery Hall-Of-Fame members, the inductees are selected based on the following criteria: demonstrated extraordinary service to the knife industry; displayed honesty, character and integrity; advanced the industry by the creativity and originality of their works or contributions; as ambassadors or outstanding contributors, have furthered the positive impact of the knife industry on the world at large, and, in summary, have demonstrated a worthiness to be a member of this prestigious group.

The latest inductees exhibit all these qualities and more and represent a most worthy Cutlery Hall-Of-Fame induction class of 2022.

Read About Past Hall Of Fame Inductees:

- Hendrickson, Imels Join Cutlery Hall Of Fame®

- Keeslar and Sornberger Join Cutlery Hall Of Fame®

- Tony Bose, Mel Pardue Inducted To BLADE Magazine Cutlery Hall Of Fame®

- BLADE Magazine Cutlery Hall of Fame Inductees Through The Years